Revving Up the Bioeconomy: How Plant-Based Materials Are Shaping EV Manufacturing

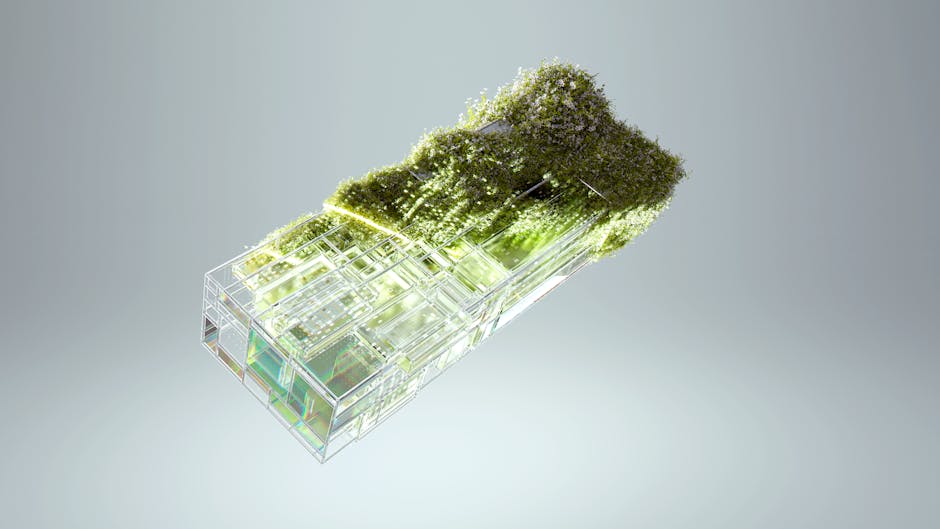

In the race toward a greener future, the automobile industry is experiencing a thrilling transformation, leveraging innovative plant-based materials to redefine electric vehicle (EV) manufacturing. An astonishing shift is happening beneath the hood of your next EV, and plant-based materials are taking center stage—promising sustainability, performance, and a new perspective on how we interact with our vehicles. This isn't just a fleeting trend; it’s a fundamental reinvention rooted in the bioeconomy that has implications far beyond the factory floor.

The Rise of Plant-Based Materials in EV Production

For years, the automotive industry has predominantly relied on metals and plastics derived from fossil fuels. However, recent advancements in bioplastics, natural fibers, and other organic materials are pushing the boundaries of conventional vehicle design. So why are manufacturers turning to plant-based materials? The benefits are manifold—ranging from lower environmental impact to enhanced performance characteristics.

Plants like hemp, flax, and jute are now being used to create lightweight composites that possess astounding durability. For instance, BMW has pioneered the use of natural fibers in their electric car interiors, demonstrating how plant-based materials can reduce weight and, consequently, increase range. These innovations hold the potential to revolutionize not just the materials used in vehicles but also the overall environmental footprint of automotive manufacturing.

Enhancing Performance While Reducing Footprint

One of the most significant advantages of using plant-based materials in electric vehicles is the potential to enhance performance while curtailing environmental impacts. A lighter vehicle means improved energy efficiency, which is particularly crucial for EVs that rely on battery power. By replacing heavy metal components with lighter, yet strong, organic alternatives, manufacturers can make strides in boosting the vehicle's range on a single charge.

Moreover, bio-based materials are often biodegradable or easier to recycle than traditional plastics. This not only reduces waste but also supports a circular economy in which materials can be reused repeatedly. Encouraging responsible sourcing practices, the burgeoning use of organic materials in EV manufacturing also prompts an important conversation about sustainability within the entire supply chain.

Case Studies: Leading the Charge in Sustainable Innovation

Numerous companies are leading the charge in the application of plant-based materials for electric vehicles, sparking hope for a future intertwined with the bioeconomy. Take Rivian, for example. The company has integrated sustainable options into their electric trucks, employing a mixture of recycled and bio-based materials throughout the interior.

Similarly, Ford has made headlines with its use of soy-based foam for seat cushions in certain vehicle models. This simple switch has reduced the reliance on petrochemical products and promotes agricultural sustainability—a win-win scenario that highlights how traditional manufacturing processes can align with modern environmental goals.

You can learn more about the sustainable practices that are reshaping urban spaces for EVs in our article on how EVs are shaping urban green spaces.

The Future of Bioplastics in Electric Vehicles

As technologies advance, the future of bioplastics appears even brighter. Innovators are working to develop higher-performance bioplastics capable of withstanding the rigors of automotive applications while maintaining environmental integrity. Research has shown that bioplastics can be engineered to exhibit properties such as UV resistance and thermal stability, positioning them as viable alternatives to traditional plastics.

These advancements could lead to a world where the majority of a vehicle's components, from interiors to exteriors, are crafted from sustainable sources, contributing to reduced carbon emissions during production and throughout the vehicle's lifecycle.

Navigating Challenges and Opportunities in EV Manufacturing

Despite the promising outlook, challenges remain in the widespread adoption of plant-based materials in EV production. While material properties can be optimized, concerns over costs and scalability must be addressed. As the technology is still in its infancy, manufacturers often face hurdles in sourcing sufficient quantities of sustainable materials at an economical price point.

Nevertheless, collaboration among industry players, educational institutions, and researchers will be crucial in overcoming these obstacles. By pooling resources and knowledge, the automotive and agricultural sectors can forge a path toward comprehensive sustainability that melds innovation with practicality. The vibrant ecosystem of research and development opportunities can help create the materials that are not only sustainable but also market-ready.

Consumer Perception: Embracing Sustainability in EVs

Interestingly, consumer perception plays a key role in the burgeoning demand for eco-friendly alternatives. Today's eco-conscious consumers are more inclined toward brands that showcase sustainability in their business practices. A survey conducted in 2023 revealed that nearly 70% of potential EV buyers factor environmental responsibility into their purchasing decisions. This increasing awareness presents an opportunity for manufacturers to capitalize on the growing trend of sustainable practices in their marketing.

Highlighting the bio-based aspects of vehicles can create a strong narrative that resonates with consumers. It not only positions companies as leaders in sustainability but also aligns their brand with the values of a new generation of environmentally aware drivers.

For further insights into how the EV landscape is evolving, consider exploring our article on the intersection of fashion and EVs, which emphasizes consumer interest in eco-conscience innovations.

The Role of Government Policy in Supporting Green Innovations

Government regulations and incentives also play a crucial role in fostering advancements in plant-based materials for electric vehicle manufacturing. As nations increasingly commit to reducing greenhouse gas emissions, many are introducing policies that promote the development and use of sustainable materials in various industries.

For example, tax incentives for companies that prioritize eco-friendly materials can help offset the initial costs associated with research and development. Additionally, grants and subsidies aimed at sustainable agricultural practices contribute to the larger picture of sustainable manufacturing by ensuring that raw materials are responsibly sourced.

The Intersection of Bioeconomy and Technology in EVs

Diving deeper into the world of electric vehicles reveals intriguing intersections between technology and sustainability. The incorporation of artificial intelligence (AI) and machine learning algorithms plays a significant role in sourcing and developing plant-based materials efficiently. By analyzing vast data sets, AI can identify the most sustainable crops for raw material production while considering factors such as yield, carbon footprint, and overall resource efficiency.

Moreover, the smart integration of EV technology can foster an eco-centered consumer experience, whether it’s through advances in battery technology, smart home integration, or predictive maintenance systems. Innovations like AI-powered predictive maintenance can significantly enhance vehicle longevity, encouraging users to be more mindful of their vehicles' impacts.

Reevaluating the Life Cycle of Electric Vehicles

The transition to plant-based materials also evokes a call to reevaluate the lifecycle of electric vehicles. What happens to a vehicle at the end of its operational life? The introduction of bioplastics and other organic materials might pave the way for new recycling methods tailored specifically to ensure minimal environmental impacts.

Closed-loop recycling systems for plant-based materials could lead to entirely renewable vehicle lifecycles. This concept not only supports the principles of a circular economy but also reduces waste significantly—a crucial element in preserving our environment.

Final Thoughts: Driving Toward a Sustainable Future

The integration of plant-based materials into electric vehicle manufacturing is not merely an industry trend; it signifies a monumental shift toward a sustainable economy and reflects a collective desire to minimize our environmental footprint. As we rev up the bioeconomy, our vehicles can become more than just modes of transport—they can represent a deeper commitment to preserving our planet.

With continuous innovation, collaboration, and consumer support for sustainable practices, the road ahead is undoubtedly greener. By investing in plant-based materials now, we are not just changing the way we manufacture vehicles; we are defining the legacy we leave for future generations.

If you’re curious about how electric vehicles are reshaping urban environments or influencing modern designs, take a look at our exploration of autonomous electric vehicles and their impacts on architecture and urban planning.