Beyond Metal: Biodegradable Materials in Future EV Manufacturing

As electric vehicles (EVs) increasingly dominate our roads, it's time to look toward an important evolution in their manufacturing: the transition from conventional metals to biodegradable materials. While many enthusiasts marvel at the power of electricity, the real unsung hero in the world of EVs may be the materials used to construct these vehicles. This exploration into innovative approaches reveals how biodegradable materials in electric vehicle manufacturing not only serve the dual purpose of sustainability but also significantly reduce the environmental footprint of production. Discover the technologies, thought leaders, and game-changing companies leading this movement on the road to an eco-friendly automotive future.

The Rise of Biodegradable Materials in EV Manufacturing

In a time when climate change looms large, the automotive industry finds itself under a spotlight for its environmental impact. Traditional vehicle manufacturing often comes with a heavy toll on ecosystems and resources. Enter biodegradable materials: a game-changing alternative that harmonizes car production with nature. This shift represents not just an enhancement in automotive design but an evolution toward a sustainable future.

Biodegradable materials have evolved notably in recent years. Advanced fibers derived from natural sources like hemp, flax, and mycelium are emerging as promising contenders for traditional insulations and plastic components. Not only are they less harmful to our environment, but they also boast properties such as lightweight and robust structural integrity, making them ideal for automotive applications.

What Are Biodegradable Materials?

Essentially, biodegradable materials consist of biological origin ingredients that can break down naturally when exposed to environmental conditions. These materials decompose into harmless substances over time, thus reducing ongoing waste and pollution. They can be classified into various categories, including:

- Plant-based Composites: These materials utilize natural fibers blended with resins, avoiding toxic chemicals typically used in plastics.

- Mycelium-based Products: These innovative options leverage fungal roots for insulation and interior elements, providing a biodegradable option while enhancing durability.

- Bio-derived Polymers: Utilizing renewable resources like cornstarch or sugarcane, these polymers can be engineered into various automotive components.

It's crucial to underscore that with continual advancements, the automotive industry is becoming more open to adopting ecomaterials in their manufacturing processes.

Innovative Technologies Revolutionizing Eco-Friendly Manufacturing

As we dive deeper into the science behind biodegradable materials, several pivotal technologies pave the way for innovation.

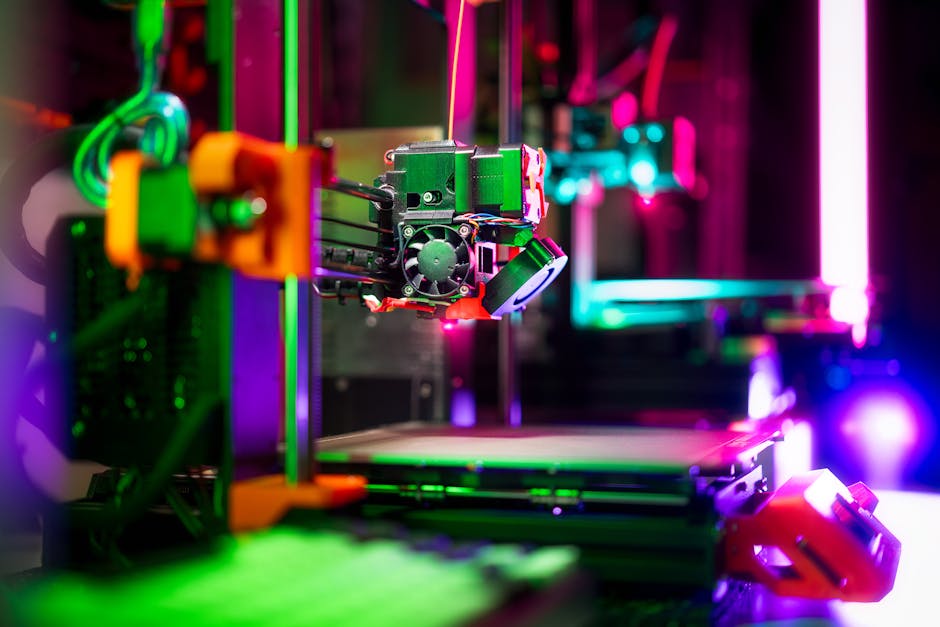

1. 3D Printing

3D printing allows manufacturers to create complex car parts using less material and energy. By combining this technology with biodegradable resins, companies can fabricate automotive components that decompose after their lifecycle. This approach optimizes resource usage while drastically minimizing waste.

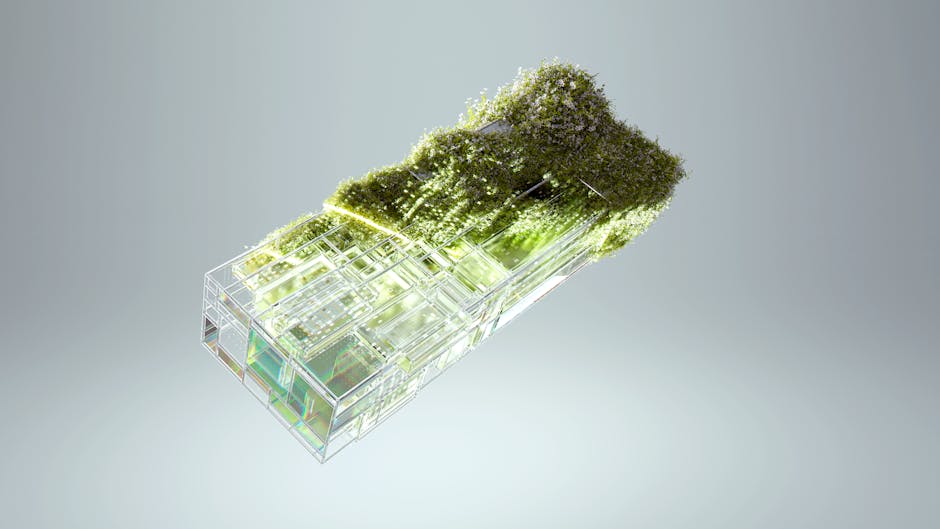

2. Bio-Inspired Designs

Nature holds many of the answers to sustainable manufacturing. Biophilic design considers nature's efficiencies and aesthetics, allowing manufacturers to incorporate environmentally friendly materials through organic shapes and patterns. Such designs can lead to reductions in excess material usage while enhancing the user’s psychological comfort, as discussed in this exploration of biophilic design in EV interiors.

3. Enhanced Recycling Systems

One of the concerns surrounding biodegradable materials is their disposal during the early stages of adoption. Emerging technologies for composting and anaerobic digestion can address these concerns, making disposal processes more efficient.

These systems will allow manufacturers to re-introduce old parts back into production cycles, further decreasing their reliance on virgin materials. This loop directly contributes to sustainability efforts while promoting a circular economy.

Leading Companies Pioneering Biodegradable Innovations

Several trailblazing companies stand at the forefront of integrating biodegradable materials into their electric vehicle designs.

Ford Motor Company

Ford has long been committed to sustainability, and with their initiative, Ford's "Sustainable Vehicle Concept," the company explores new composite materials that reduce weight and lower carbon emissions during production. Their push toward using plant-based materials within car interiors aligns with the larger goal of a greener automotive future.

BMW Group

BMW is pushing boundaries with the use of mycelium, changing the game in both sustainability and design. Their initiative employs fungal materials for seat upholstery, packaging, and components, blending luxury with eco-friendliness. As a company committed to Future Mobility, BMW's efforts may serve as a blueprint for sustainable practices in the automotive industry.

Tesla

As global leaders in electric vehicles, Tesla recognizes sustainability goes beyond just eco-friendly batteries. Their ongoing research into biocomposite materials aligns with their vision of utilizing greener materials throughout their product line.

Expert Insights: A Dialogue with Industry Leaders

To gain further insights into the future of biodegradable materials, I spoke with industry leaders grappling with the intersection of sustainability and technology in automotive design.

Dr. Sarah Thompson, a Materials Scientist at Green Tech Innovations, emphasized the importance of ongoing research: "We are not just revolutionizing the materials themselves; we’re also investing in better designs and recycling methods. Our responsibility extends beyond the factory floor into the consumer's hands."

Mark Collins, the Chief Sustainability Officer at Tesla, shared his thoughts on the long-term vision of EV manufacturing: "Adoption of biodegradable materials aligns with our mission of creating the most sustainable vehicles possible, and we're seeing innovators expand the frontiers of materials science."

Case Studies: Success Stories in Eco-Friendly Manufacturing

Diving into real-world implementations offers a concrete path for understanding these concepts. Here’s a closer look at a few case studies highlighting the pioneering work being done in this environmentally-conscious sector.

Case Study 1: Ford's Sustainable Vehicle Program

The Ford Motor Company has been experimenting with various sustainable materials within their vehicles. Their initiation of plant-based composites for seat foam and interior trims has yielded promising outcomes, reducing reliance on non-renewable resources.

Case Study 2: BMW’s Circularity Strategy

BMW aims for complete circularity by 2030. Their strategy focuses on increasing the use of recycled materials and reducing waste, marking a significant shift towards a more sustainable approach in manufacturing electric vehicles. According to BMW, their goals encompass using up to 50% recycled materials in key components.

Case Study 3: Tesla's Material Science Initiatives

Tesla’s innovative use of biocomposites in their interior manufacturing process highlights a forward-thinking approach to vehicle design. By recognizing the environmental toll of traditional materials and actively pursuing biodegradable alternatives, Tesla stands out in automotive innovation.

The Environmental Impact of Biodegradable EVs

Transitioning toward biodegradable materials has the potential to reduce greenhouse gas emissions significantly. Traditional vehicle production often generates substantial carbon footprints, from the mining of metals to the energy-intensive processes used. On the other hand, adopting biodegradable materials can mitigate these impacts.

LCA: Life Cycle Assessment

In measuring the overall environmental benefits of biodegradable materials, Life Cycle Assessment (LCA) becomes essential. By analyzing each stage—from raw material extraction to product disposal—LCA provides clarity on the sustainability of manufacturing processes. Initial studies indicate that biodegradable materials can reduce negative impacts by as much as 30%!

The Broader Implications for Society

The effort to embrace biodegradable materials in EV manufacturing extends well beyond singular companies.

Community Empowerment and Innovation

As awareness of sustainability grows, communities are increasingly rallying around local businesses that prioritize eco-friendly practices. Companies that adopt biodegradable materials contribute to community efforts focused on environmental conservation. In addition, collaborative initiatives between automakers and universities must foster innovation in materials science, driving more artists and scientists to the forefront of sustainable automotive design.

Next Steps Toward a Greener Future

Greener automotive manufacturing is more than just using alternative materials; it involves a holistic approach to sustainability. From front-end design to the recycling stage, enrolled stakeholders must realize their accountability.

Collaboration is Key

For meaningful progress, industry stakeholders—automakers, researchers, government authorities, and consumers—must collaborate. Greater transparency about material sourcing and end-of-life processes will encourage buyers to become informed advocates for biodegradable vehicles.

Ongoing Research and Development

Continual investment in R&D is indispensable for improving these materials, enhancing their performance while ensuring they remain accessible. The more we innovate, the more sustainable our electric vehicles can become.

Final Thoughts

The future of electric vehicle manufacturing lies in the embrace of biodegradable materials, a sustainable approach that addresses the pressing environmental challenges we face today. With leading companies pioneering this significant shift, a world where eco-friendly vehicles dominate our streets is not just a dream—it's a possibility within our grasp.

Shifting from metal to biodegradable materials in EV manufacturing is not merely about following trends; it fundamentally reshapes our relationship with the environment, offering a clear path toward a sustainable future in transportation.

By making informed decisions today, we can foster an eco-conscious society, elevate public awareness, and shape a movement embraced by audiences around the globe.

For more insights into how electric vehicles are positively transforming urban landscapes, check out our article on urban public transport with EVs for additional explorations into this evolving industry.