3D Printing Revolution: Customized EV Parts Transforming the Industry

The world of electric vehicles (EVs) is undergoing an exhilarating transformation, and at the heart of this revolution lies an innovative technology: 3D printing. From enabling a new level of personalization to slashing manufacturing costs and bolstering sustainability, the impact of 3D printing on the production of EV parts and accessories is nothing short of remarkable. As car enthusiasts embrace customization and manufacturers adapt to a changing landscape, it’s crucial to explore how this technology is reshaping the future of electric vehicles.

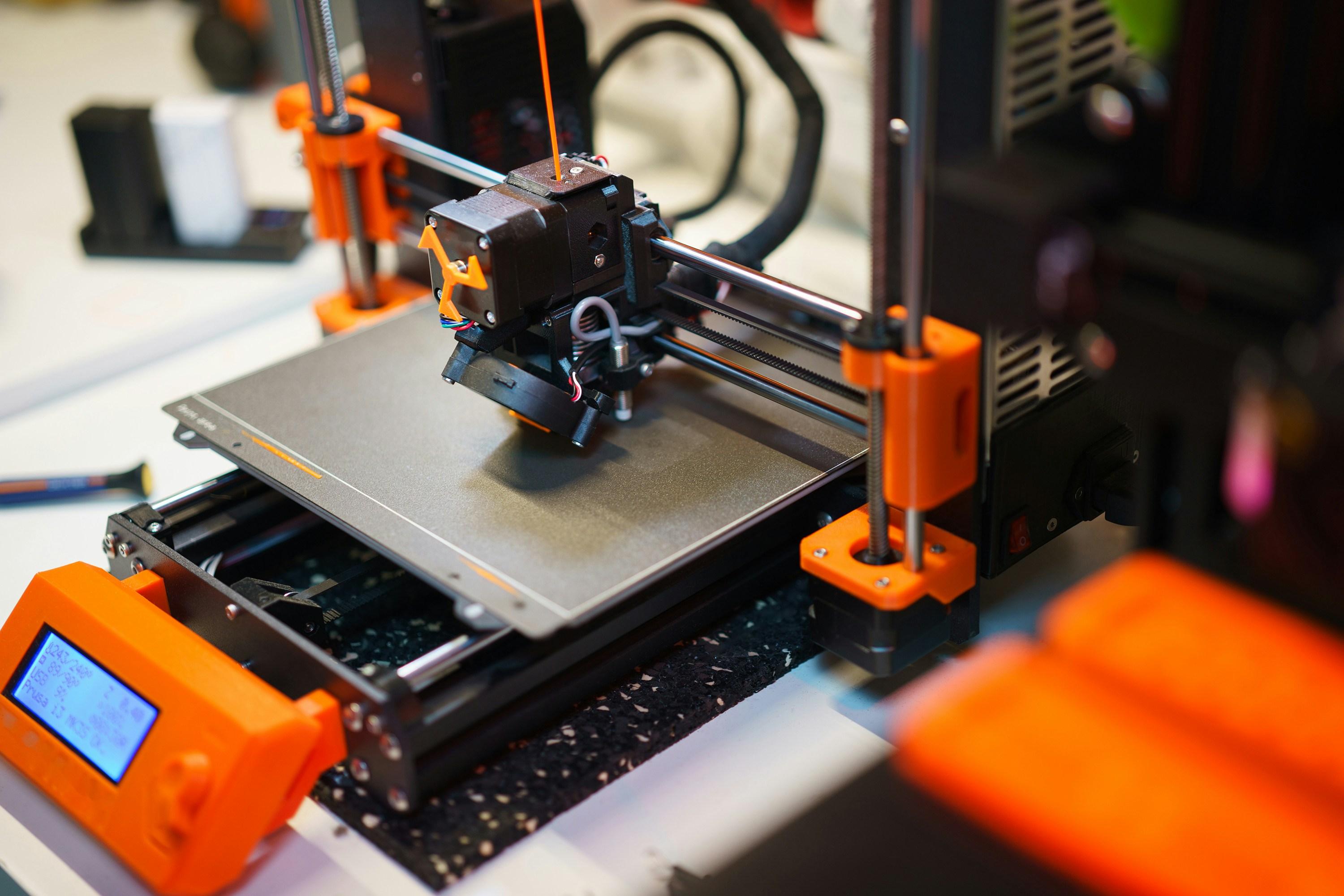

The Rise of 3D Printing in the Automobile Sector

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. In the past decade, this technology has taken industries by storm, and the automobile sector is no exception. Traditional manufacturing methods often involve lengthy production times, high costs, and enormous waste. However, with 3D printing, manufacturers can produce parts on-demand, significantly reducing lead times and material waste.

Achieving Personalization

One of the most compelling appeals of 3D printing in the EV market is its ability to create customized parts tailored to the unique preferences of individual consumers. Imagine ordering a custom dashboard design with your favorite color scheme or personal graphics, all produced to fit your vehicle perfectly. Such personalization not only enhances the aesthetic appeal of the vehicle but also fosters emotional connections between owners and their cars.

Consumers increasingly crave products that reflect their identity and lifestyles. This surge in demand for personalization signifies a major shift in automobile manufacturing, allowing 3D printing to address consumer desires efficiently. Moreover, as an experiment highlighted in Harvard Business Review, companies that engage with consumers on a personal level strengthen brand loyalty and increase customer satisfaction.

Reducing Manufacturing Costs

The cost-effectiveness of 3D printing cannot be overstated. Traditional manufacturing often necessitates large-scale production, meaning companies invest heavily in machinery, workforce, and raw materials. In contrast, 3D printing drastically reduces these overheads by allowing for small-batch production or even one-off manufacturing without extensive setup costs. Parts can be designed and produced as needed, minimizing storage requirements and reducing the risk of excess inventory.

As automotive companies navigate financial hurdles and strive to remain competitive in the growing EV market, leveraging 3D printing technologies presents a valuable opportunity. For instance, Ford has embraced 3D printing not only for prototyping but also for manufacturing parts, realizing savings that allow them to invest in more sustainable practices.

The impact of reducing production costs can be felt by consumers too; manufacturers may pass savings onto buyers, making electric vehicles more accessible to a broader audience. You can read more about how embracing new technologies can lead to overall savings in an insightful article from Moz.

Environmental Benefits and Sustainability

Another pivotal advantage of incorporating 3D printing into EV manufacturing is its support for sustainability initiatives. The automotive industry faces increasing scrutiny for its environmental impact, and the shift towards electric vehicles is an essential step in reducing carbon footprints. However, the production process of traditional vehicles still contributes significantly to waste and pollution.

3D printing aligns with the growing focus on sustainable practices by minimizing waste materials and enabling the use of eco-friendly resources. Parts can be fabricated with precision, resulting in less excess material. Furthermore, advancements in 3D printing now allow companies to experiment with biodegradable and recyclable materials—creating parts that are not only custom-designed but also environmentally conscious.

Notably, startups in the industry are pioneering the use of recycled plastics and bio-based materials in 3D printing. Companies such as Local Motors are at the forefront in utilizing such methods to create zero-emission vehicles that boast efficiency and sustainability. This shift will complete the cycle of eco-friendliness that EVs inherently promote—making them not just green in operation but also in production.

Real-World Examples

Real-world implications of 3D printing in the automotive industry are evident across several leading manufacturers. Tesla, for example, has incorporated 3D printing technologies in its production processes, famously using it to create unique parts like cup holders and assembly aids. Their forward-thinking approach has positioned them as a leader in both innovation and sustainability within the EV space.

Another compelling case is the partnership between BMW and Sculpteo, a 3D printing company, aimed at streamlining the production of parts. BMW’s investment in 3D printing technology has reduced production lead times for several models by utilizing custom-designed components that fit their specifications. By hosting workshops to encourage engineers to create their designs for prototypes, they're not only reducing costs but also cultivating a culture of innovation within their teams.

Expert Opinions: The Future of 3D Printing and EVs

To thoroughly understand the implications of 3D printing in the EV industry, we must consult industry experts who can provide deeper insights. According to Dr. Ellen Leanza, an expert in additive manufacturing, “The adoption of 3D printing in the automotive industry signifies a shift not just in manufacturing but also in the design philosophy. It facilitates a creative process where engineers can experiment without extensive costs, fostering innovation."

Adding to this, car enthusiast communities have also spoken favorably about the emergence of customized parts. Many are eager to share their experiences and the personal touch they can impart on their vehicles. The role of community in driving interests around 3D printing for electric vehicles is significant, further emphasizing how consumers crave bespoke experiences in their automotive journeys.

The Future of Customization

As we look to the future, it’s evident that the customization of electric vehicles through 3D printing is set to grow even more expansive. With continued advancements, it’s possible that more manufacturers will adopt localized production using 3D printing facilities that can churn out tailored parts rapidly. These innovations will not only cater to consumer preferences but also allow manufacturers to respond swiftly to market trends without embarking on extensive retooling processes.

Moreover, as virtual reality (VR) and augmented reality (AR) technologies evolve, we may witness a closer synergy between design and consumer preferences. Imagine utilizing VR technology to design and order tailored parts in real-time, enhancing user engagement and satisfaction.

The innovation doesn’t end with vehicle parts; the realms of interior customization and accessories extend the potential of 3D printing in electric vehicles. Understanding how to catapult into this evolving landscape is critical for consumers and manufacturers alike.

Next Steps: Embracing the Future of EV Customization

As electric vehicles continue to define the future of mobility, the impact of 3D printing on customization is profound. For consumers, the opportunity to personalize their vehicles presents an exciting avenue to express individuality, while manufacturers can leverage this technology to create a more sustainable and cost-effective production line.

If you're curious about how customization shapes the EV experience, we invite you to explore related topics such as AI personalization in driving or find out how electric vehicles enhance urban environments in our article on urban evolution by EVs.

With technological advancements unfolding, the narrative of electric vehicles is set to take many fascinating twists and turns, with 3D printing leading the charge. Embrace this evolution, and consider how your next vehicle might reflect your unique taste, all while contributing to a more sustainable future.